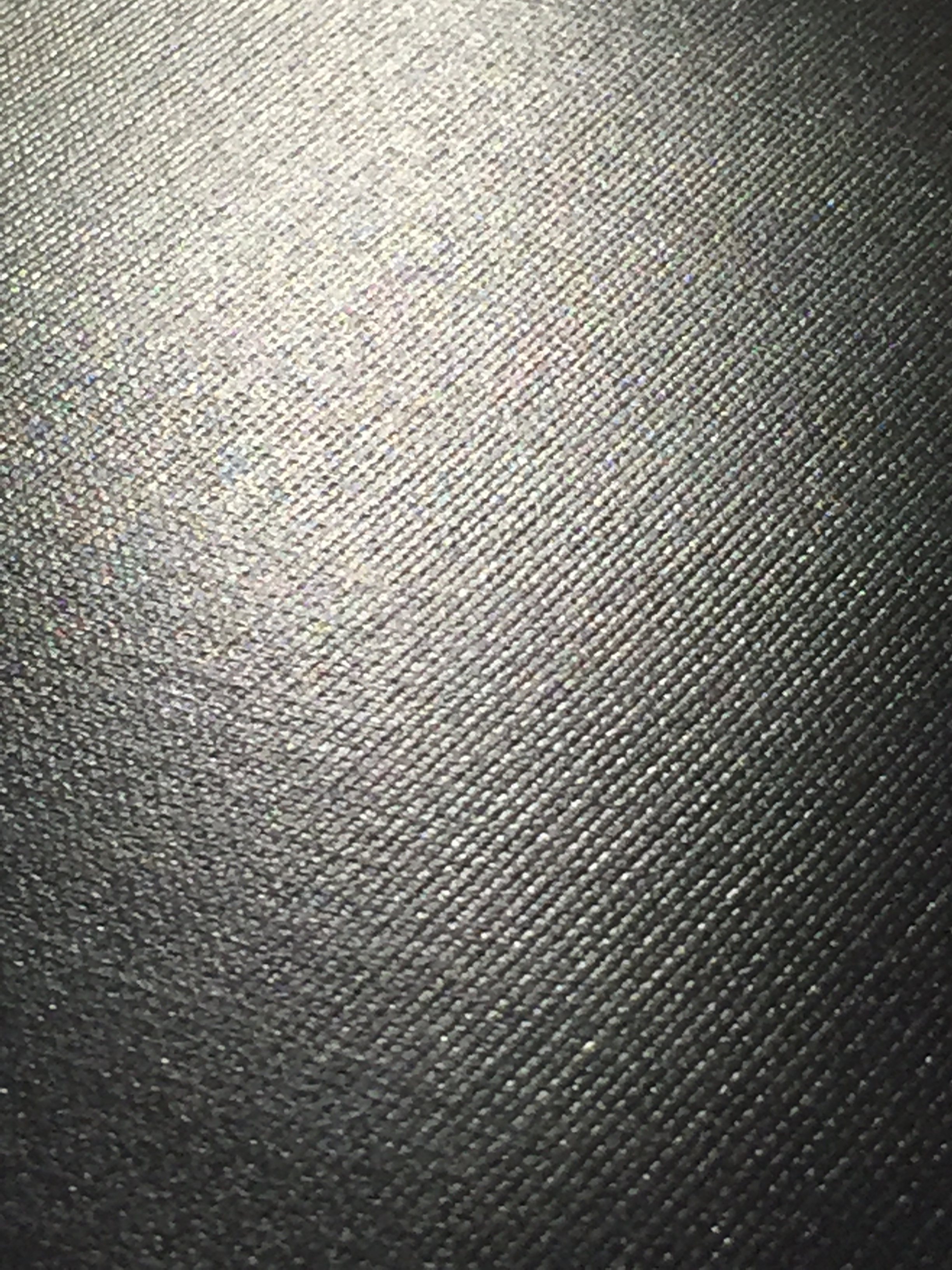

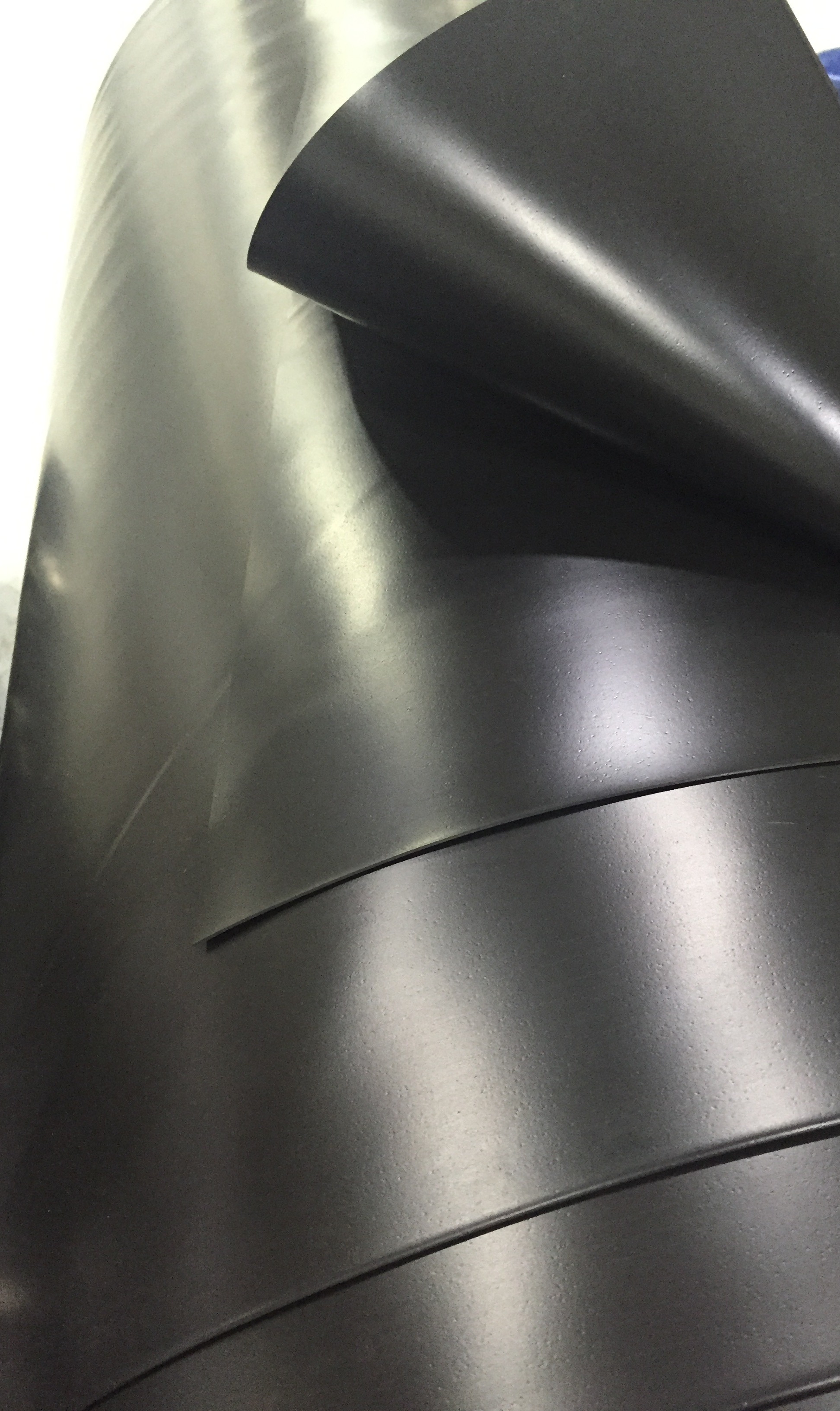

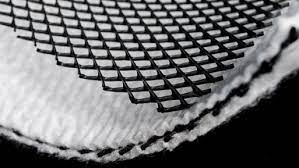

Geonets are typically formed by two bi-planar sets of relatively thick, parallel, polymeric (usually polyethylene) ribs bonded in such a way that the two planes of strands intersect at a constant acute angle, forming a diamond-shaped pattern. They can also be manufactured in Tri-Planar configuration. Geonets are used extensively in drainage applications and as leak … Geonet & Geocomposite